Key UC Contact

What We Did

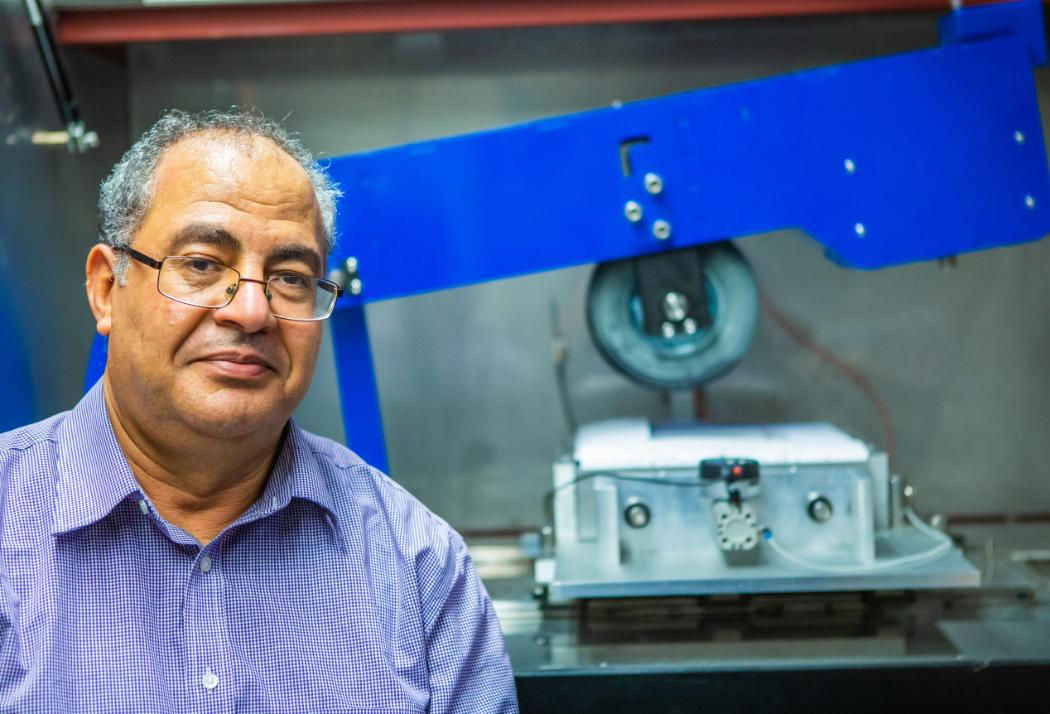

The research work conducted on the permanent deformation behaviour of asphalt materials has led to an improved testing system and new international standards. This enhanced testing system for road materials can make our state highways safer and more robust to withstand years of heavy traffic. A new, modified “wheel tracker” device developed by University of Canterbury (UC) Professor of Civil Engineering Mofreh Saleh is a more reliable way of testing the stability and permanent deformation resistance of the materials used to construct new roads. The new device is patented in the US and European Union under US10883906B2 and EP3479095B1. Prof Saleh says, “it’s very important to identify weak materials at the design phase to avoid them failing after they’ve been built”.

Why It Matters

In NZ, there were many examples of premature failure and repeated repairs that prematurely fail. More recently, for example, the cost of repairing cracking and rutting in the Kāpiti Expressway and the Te Rapa and Ngaruawahia sections of the Waikato Expressway topped $80 million.

Prof Saleh explains, “These premature problems can be avoided with better and more rigorous testing methods to identify the performance of road materials. This in turn will lead to long lasting and more stable infrastructure”. Poor quality road materials can lead to “rutting” in the road surface causing ruts and dips where water accumulates. Accidents can happen when drivers hit these uneven, wet areas at normal speed and lose control. Most of us drive every day on the roads and the last thing we want is to encounter hazards caused by deep rutting filled with rainwater that can lead to hydroplaning/aquaplaning – losing traction in wet conditions - and increased risk of motor accidents.

There is also the cost and inconvenience caused by road maintenance and repairs having to be carried out more frequently. People end up spending more time stuck in traffic due to lane closures and we have to spend millions of dollars of taxpayer money to repair poorly constructed infrastructure. The modified system and the new test protocol give a more reliable testing result than the conventional testing system and it can be used for granular roading material as well as asphalt.

“The existing technology often gave inaccurate results – false negatives or false positives - so the material might seem safe but didn’t perform well when it was used in the field”, Prof Saleh says. In February 2020, the American Society for Testing and Materials (ASTM) adopted a new standard ASTM D8292: Permanent Deformation Behaviour and Rutting Resistance of Compacted Asphalt Mix in the Modified Loaded Wheel Tracker Test Utilizing Controlled Confining Pressure. This new standard is based on Prof Saleh research work at the UC in the permanent deformation area.

The new standard is now available to highway agencies and practitioners at:

www.astm.org/Standards/D8292

Learn More

There are several peer reviewed publications on the new system and its advantage over the conventional systems.

- Saleh, M. (2020). Modified wheel tracker as a potential replacement for the current conventional wheel trackers. International Journal of Pavement Engineering, 21(1), 20-28

Chowdhury, R. A. Saleh, M. F. and Gonzalez, M.M. Investigation of the permanent deformation of HMA based on dynamic creep test and modified wheel tracker, Canadian Journal of Civil Engineers, 2021. - Chowdhury, R. A. Saleh, M. F. and Gonzalez, M.M., Ruggedness Testing of the Factors Affecting the Permanent Deformation Behavior Studied Under the Modified Wheel Tracker (MWT), ASCE International Airfield & Highway Pavements Conference, 2021.

- Chowdhury, R. A., Saleh, M. F., and Gonzalez, Precision Assessment of the Modified Wheel Tracking Device Based on Small-Scale Testing of New Zealand Hot Mix Asphalt, the 9th International Conference on Maintenance and Rehabilitation of Pavements (MAIREPAV9), Zurich, 1 - 3 July 2020.

- Chowdhury, R. A., Saleh, M. F., and Gonzalez, M. M. An Investigation of the Permanent Deformation Behavior of Hot Mix Asphalt Utilizing 1 Dynamic Creep Test and Modified Wheel Tracker, Journal of the Transportation Research Board annual meeting, Washington DC, 2020.